The World’s Most Natural Circuit Board

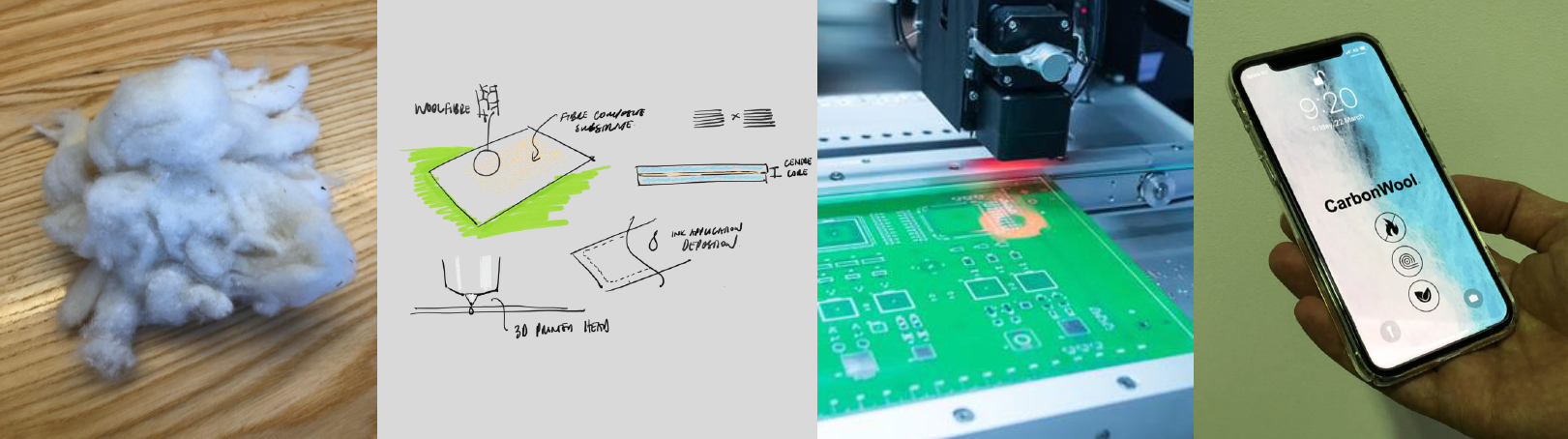

“We thought, what’s the most audacious thing that can be done with wool? So we decided to replace the Printed Circuit Board.” Designer Blythe Rees-Jones explains the thought process that led his team to create the world’s most natural circuit board out of New Zealand’s natural wonder material, wool.

World famous in New Zealand

If you want to transform an industry you need new thinking. Our journey started by thinking; ‘what is the most audacious thing we could do with wool?’

Enter the silicone chip, or integrated circuit. It is one of the biggest innovations in human industry. This invention is so significant the region where it was invented is known as “Silicone Valley” and it has become a focal point for technological invention the world over.

Every silicone chip is mounted on a circuit board, referred to in the industry as a Printed Circuit Board or PCB. These PCBs are everywhere, inside all digital and electronic devices we use daily. The global PCB market is expected to reach an estimated $80.1 billion by 2023 and it is growing at a CAGR of 3.3%.

It has been many-a-kiwi business dream to crack it big in the tech sector. So image the excitement when the Virtuo team from New Zealand’s little innovation quarter of Tauranga created the world’s first circuit board out of wool, CarbonWool® to be exact. They might just be on to something!

The problem

Today roughly 40 million metric tons of electric waste (e-waste) is produced globally each year. E-waste has fast become a significant global environmental and human health issue, all the while demand for these smart circuits continues to rise as we connect our world.

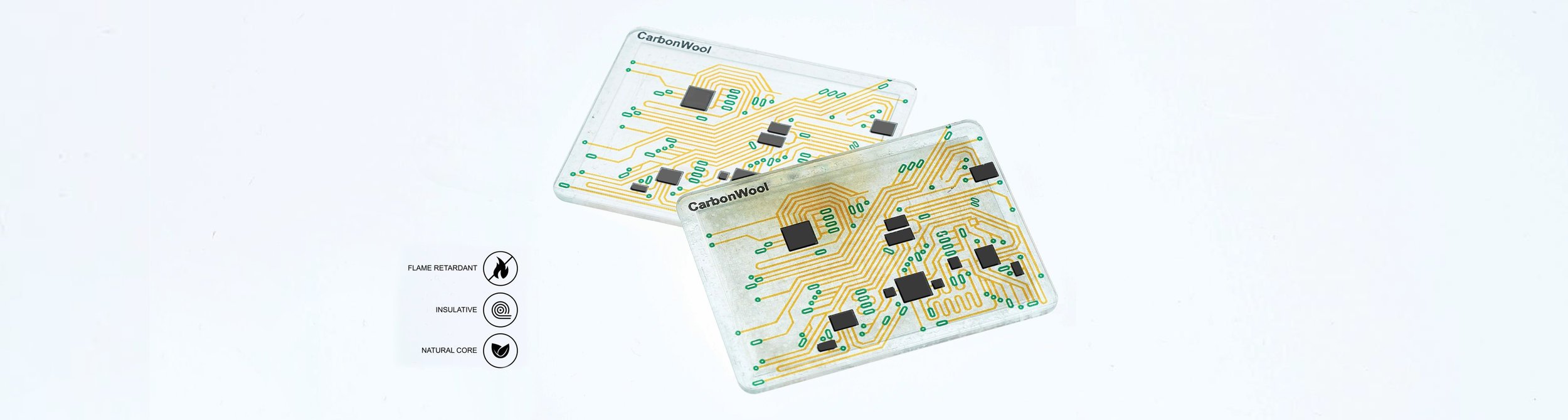

All PCBs are made using toxic materials: lead in the solder and cathode ray tubes, toxic fire retardants, harsh solvents and fluorocarbons and volatile organic compounds in layered assembly - as well as the precious metals in the circuitry. The thing is, in the centre of every single everyday PCB is a synthetic fibre, reinforced, hazardous fire retardant core that is impregnated with polyepoxide resins. The job of the PCB core is to protect again fire (from short-circuiting) and to insulate each side of the PCB (against electrical interference). The centre core is then sandwiched between two or more layers of printed plastic and circuit materials.

Wool re-wired

There are two things irrefutable about wool:

1) It will never burn. Nope, not at all. It’s natures own natural flame retardant due to its naturally high nitrogen and water content which requires more oxygen than is available in the air to become flammable and

2) it is a brilliant insulator.

Understanding this, we thought why not try and reinvent the centre-core of the modern electronic circuit and offer up a bio-based alternative to this billion dollar category. I can hear Intel calling.

CARBONWOOL® is a bold new disruptive concept

After working out, through trial and error, how we could do this (sorry we can’t share the secret just yet!) we started to fabricate these two new materials into a thin PCB. It’s amazing what you can achieve in a design sprint. This idea is the subject of a novel patient application.

So say hello to CarbonWool® - the world’s most natural circuit board and watch this space!

Designers: Blythe Rees-Jones and Nathan Collier